Ozone treatment technology hinges on the safe, efficient application of an ozone compound to all types of medical waste, reducing its volume up to 90%.

The reactivity of the ozone compound destroys bacteria on contact. With the push of a button, your waste is weighed, shredded, sterilized and transferred to a disposal container.

Ozone treatment technology hinges on the safe, efficient application of an ozone compound to all types of medical waste, reducing its volume up to 90%.

The reactivity of the ozone compound destroys bacteria on contact. With the push of a button, your waste is weighed, shredded, sterilized and transferred to a disposal container.

How it works

Ozone, a higher energy state of oxygen, is a molecule composed of three oxygen atoms – O3.

Ozone’s reactive nature enables it to destroy the cell walls of bacteria and viruses upon contact.

By exposing the waste’s surface area to O3 for a sustained time, the materials become sterilized. Ozone’s short-half life means it rapidly decomposes back to the stable oxygen molecule.

A higher energy state of oxygen, Ozone, is a molecule composed of three oxygen atoms – O3.

Ozone’s reactive nature enables it to destroy the cell walls of bacteria and viruses upon contact.

By exposing the waste’s surface area to O3 for a sustained time, the materials become sterilized. Ozone’s short-half life means it rapidly decomposes back to the stable oxygen molecule.

Ozone, a higher energy state of oxygen, is a molecule composed of three oxygen atoms – O3.

Ozone’s reactive nature enables it to destroy the cell walls of bacteria and viruses upon contact.

By exposing the waste’s surface area to O3 for a sustained time, the materials become sterilized. Ozone’s short-half life means it rapidly decomposes back to the stable oxygen molecule.

Anonymous

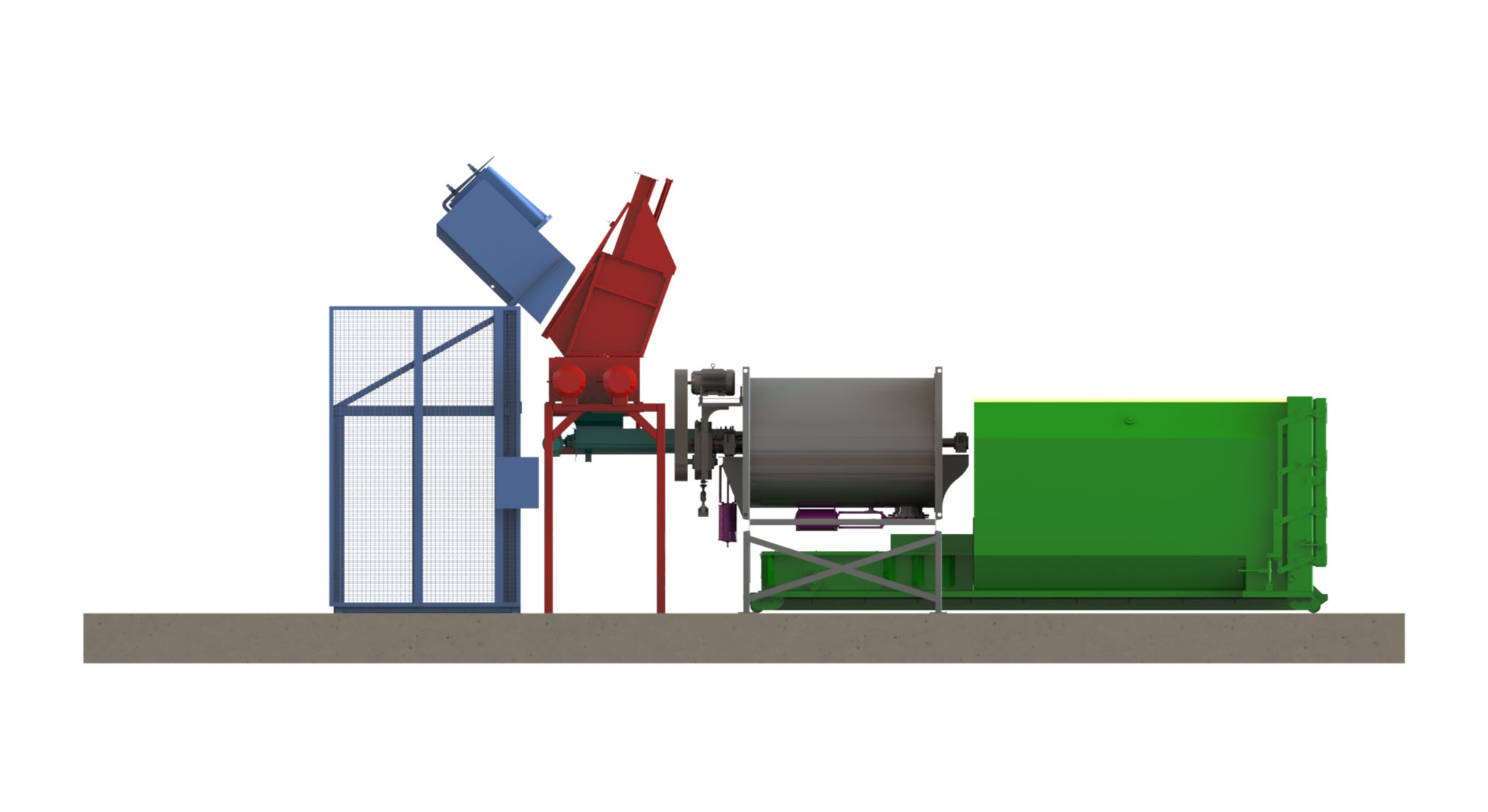

The Vortex system from WasteMedX lets you log the waste using either a bar code or source code, thereby documenting the various waste streams.

The waste is then weighed, creating a digital record of what’s being treated.

Finally, the lift raises so that the waste can be dumped into the shredder.

Shredding reduces the physical volume of the waste by approximately 90%, at a size that complies to HIPAA destruction requirements. The waste becomes unrecognizable as biohazardous medical waste, with an increased surface area that readies it for sterilization by the ozone gas.

The Ozone Treatment Chamber (OTC) contains the ozone gas and completely sterilizes the waste to a 6-log kill, or a 99.9999% sterilization rate, inside its stainless-steel shell.

Oxygen in the air is concentrated and energized by the ozone generator producing the ozone gas. The OTC agitates the waste, increasing exposure of shredded waste materials to the ozone gas.

Compaction reduces the volume of materials, increasing how much you can transport with each trip to the landfill.

As the bin is filled, a warning light and electrical signal is activated at the 75% level and another at 100%.

Next, the bin unit, a rollback design compatible with standard waste hauling equipment, can be transported to most landfills, eliminating costly disposal in a hazards-specific landfill.

Quickly log, weigh, and lift your waste into the shredder.

Reduce volume by 90%, readying the waste for sterilization.

Agitate and completely sterilize the waste to a 6-log kill.

Rollback bin is ready to be hauled to a standard, non-hazardous landfill.

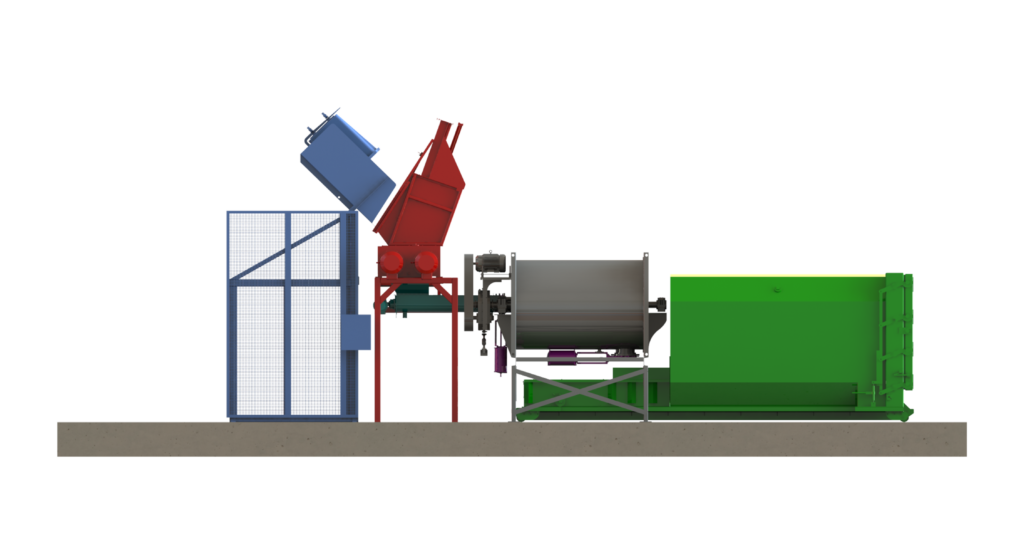

The Vortex system from WasteMedX lets you log the waste using either a bar code or source code, thereby documenting the various waste streams.

The waste is then weighed, creating a digital record of what’s being treated.

The lift raises so that the waste can be dumped into the shredder.

Shredding reduces the physical volume of the waste by approximately 90%, at a size that complies to HIPAA destruction requirements. The waste becomes unrecognizable as biohazardous medical waste, with an increased surface area that readies it for sterilization by the ozone gas.

The Ozone Treatment Chamber (OTC) contains the ozone gas and completely sterilizes the waste to a 6-log kill, or a 99.9999% sterilization rate, inside its stainless-steel shell.

Oxygen in the air is concentrated and energized by the ozone generator producing the ozone gas. The OTC agitates the waste, increasing exposure of shredded waste materials to the ozone gas.

Compaction reduces the volume of materials, increasing how much you can transport with each trip to the landfill.

As the bin is filled, a warning light and electrical signal is activated at the 75% level and another at 100%.

The bin unit, a rollback design compatible with standard waste hauling equipment, can then be transported to most landfills, eliminating costly disposal in a hazards-specific landfill.

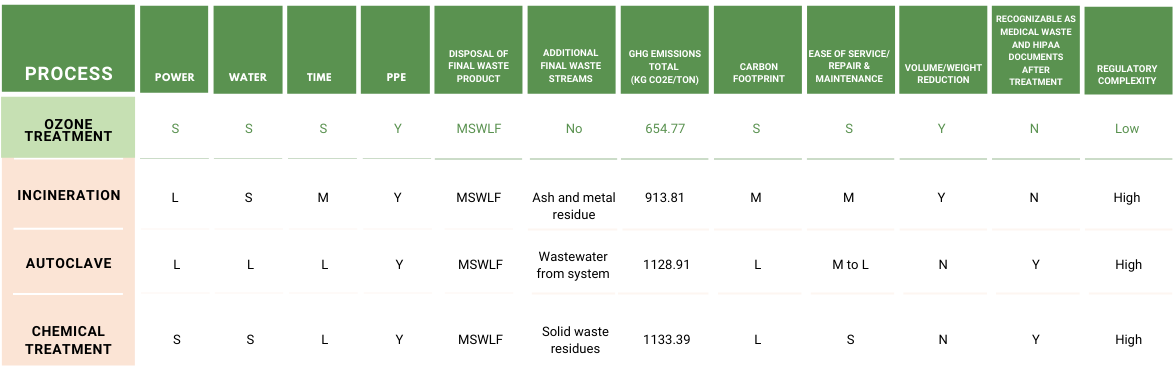

The numbers speak for themselves. See how we stack up against your current waste disposal methods.

Reach out today to learn more about our eco-friendly medical waste disposal process, Vortex technology, and how we can help your hospital save money while meeting your sustainability goals.